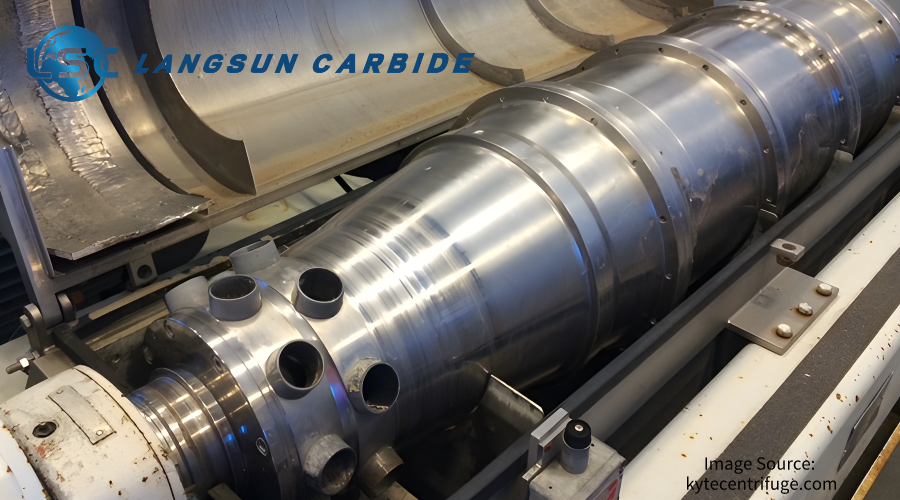

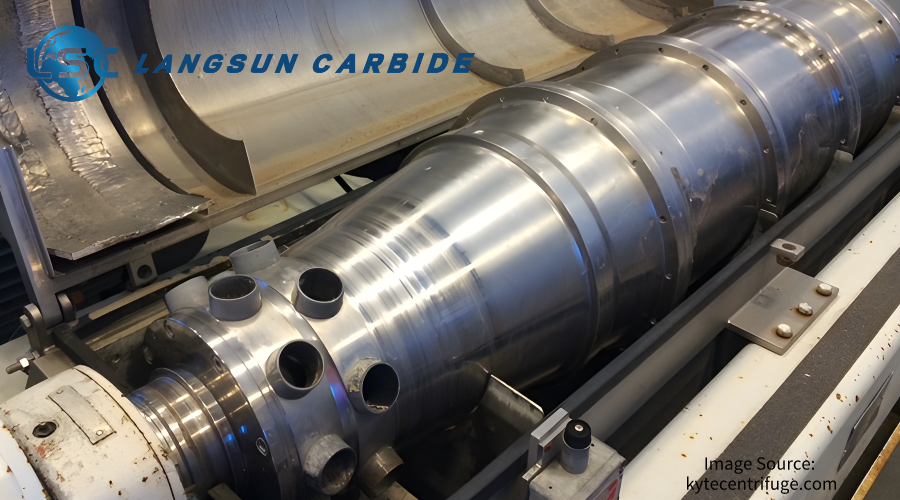

Decanter centrifuge is a kind of equipment that utilizes centrifugal force for material separation, which is widely used in many fields such as chemical, food, pharmaceutical, mining and environmental protection. This equipment mainly consists of a rapidly rotating cylinder (decanter) that has a slightly smaller screw conveyor inside, with a slight difference in rotational speed between the two.

Working principle of decanter centrifuge:

When the suspension (mixture of solid and liquid) enters the decanter centrifuge, due to the high-speed rotation, the solid particles are thrown to the cylinder wall by centrifugal force, forming a solid layer. While the lighter liquid forms an inner layer. Through different speed differences, the spiral conveyor of the decanter centrifuge separates the solid material from the liquid and conveys it to one end of the machine, while the clean liquid flows out from the other end.

- Abrasion resistance: In decanter centrifuges, due to the large amount of particle abrasion in the solid-liquid separation process, the abrasion resistance of the machine is required to be extremely high. Tungsten Carbide Centrifuge Tile can effectively resist this wear and significantly extend the service life of the centrifuge.

- Corrosion resistance: In handling some special substances, such as chemical, mining and wastewater treatment processes, decanter centrifuges may come into contact with various corrosive liquids. Tungsten CARBIDE CENTRIFUGE TILES have good chemical stability and can resist corrosion by acids, alkalis and other harmful substances. It can protect the centrifuge from the erosion and corrosion of these substances.

- Impact resistance: Tungsten carbide centrifuge tiles have good impact resistance and can withstand the shocks and vibrations that may be encountered in the operation of the centrifuge.

Application of tungsten carbide centrifuge tile:

Tungsten Carbide Centrifuge Tiles are mainly used in the key parts of decanter centrifuges, such as the protective sleeve of the separation zone, the edge of the screw conveyor, and the discharge port of the centrifuge. These parts are the most serious areas of wear and corrosion, and the use of tungsten carbide centrifuge tiles can effectively protect these parts from premature damage.

What are the advantages of choosing tungsten carbide to manufacture centrifuge tiles?

In decanter centrifuges, in addition to tungsten carbide, other wear-resistant materials such as stainless steel and ceramics are often used.

Tungsten Carbide vs Stainless Steel:

- Wear resistance: Although stainless steel has good corrosion resistance and sufficient strength, its wear resistance is much worse compared to tungsten carbide. The hardness of tungsten carbide far exceeds that of stainless steel, so the wear rate of tungsten carbide centrifuge tile is significantly lower than that of stainless steel when dealing with materials containing hard particles.

Tungsten Carbide vs Ceramic:

- Impact resistance: While ceramic materials have excellent wear and corrosion resistance, they are generally fragile and not suitable for shock or vibration. In contrast, tungsten carbide can withstand higher impacts, making it suitable for a wider range of working conditions.

- Machinability: Tungsten carbide can be machined into complex shapes more easily than ceramics, which provides greater design flexibility. Langsun Carbide can customize tungsten carbide centrifuge tiles to meet the needs of customers' centrifuge applications.